Attention To Detail and Dedication

With over 30 years of combined manufacturing experience, architects, owners, and design professionals have partnered with Metrix Group to find solutions for their most challenging perforated metal projects.

To achieve the industry leading, consistent results we’re proud of today – we have developed a tried and tested process that assists in completing complex designs. This collaborative framework is designed to meet each project’s aesthetic and functional goals within a predicable timeline and budget.

As innovators in the perforated metal industry, Metrix Group invests heavily in Research and Development and we’re proud to report that some of our best advancements have been a direct result of early architectural and contractor collaboration.

Through each step, Metrix Group takes a proactive approach to meeting project requirements and exceeding client expectations.

-

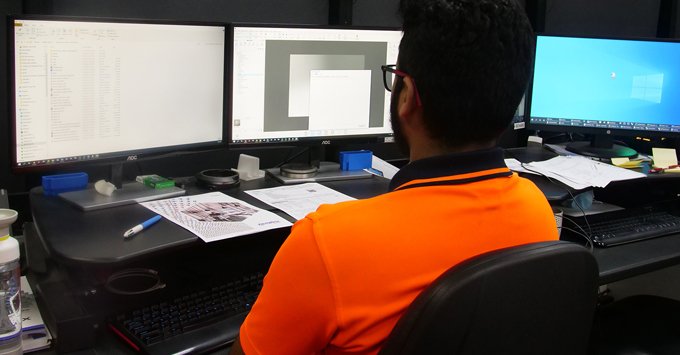

The Metrix Group in-house Design Studio brings a combination of management, design and engineering expertise to each project. From custom design and prototyping to fixing systems and installation recommendations – we strive to add value and predictability. here

-

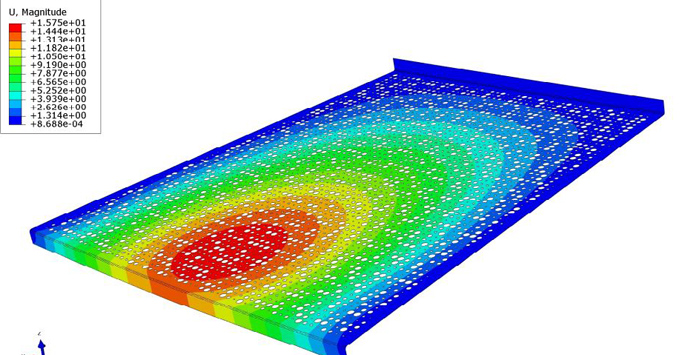

Engineering

Metrix Group engineers provide services to architects, contractors, engineers and many other stakeholders. Read more about the advancements and processes that we take before completing each project here

-

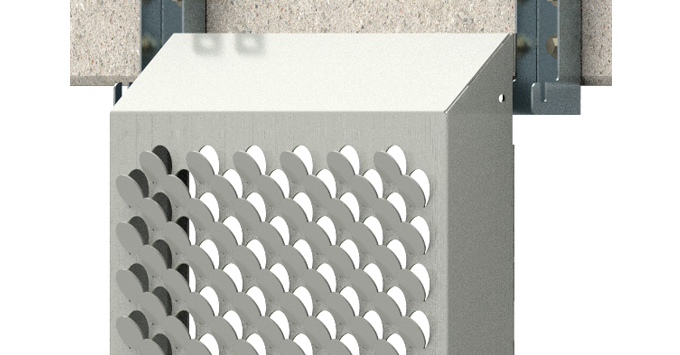

Fixing Systems

Architects and Designers can have peace of mind specifying Metrix Group proprietary fixing systems. Read more about our individual fixing systems and their advantages here

-

Sample Library

Metrix Group carry a large range of pre-made samples ready for delivery. Visit our product page to order your samples or speak to one of our technical sales staff about the creation of bespoke samples for your project.

-

Sales & Estimating Team

We pride ourselves on a 24-48 hr response time to all quotes.

We offer Formal and Informal quotes based on customer supplied architectural drawings and finish schedules.

-

Order Placement

- We pride ourselves on a 24-48 hr response time to all communication.

Our Internal Sales Coordinator will be in touch with you to confirm - Official Sales Order Acknowledgement /

- Job ref # for project tracking through production/dispatch

- Terms of Sale – Credit Status or – Estimated dispatch date.Pre-Payment – Tax Invoices/Deposits required

- Estimated dispatch date

- We pride ourselves on a 24-48 hr response time to all communication.

-

Drafting Team

To expedite your perforated panels, Metrix Group will require customer supplied final workshop drawings (panel outlines) in a single scaled 1:1 CAD file (dwg/dxf) and a jpeg image for picture perforation.

From this – Metrix Group’s drafting team will re-create;

- All Panel Outlines.

- Populate all Perforated areas & Unperforated borders/margins.

- Check fixing hole requirements.

- Check folding tolerances (if folded panels).

- Apply Unique ID Dot Font Labels.

- Re-Issue Online Approval drawings via Adobe Sign.

- Nesting & Programming.

Punching Team

Metrix Group utilise the latest in European Perforating machines. We have the facility to run machines almost completely autonomously – but nothing will ever replace the human element regardingin eye for quality and creative execution.

Tension Leveling Team

Perforating the material results in significant inner tension as well as a considerable degree of unevenness. Consequently, every perforated sheet supplied by Metrix Group is tension levelled to reduce the tension and eliminate unevenness.

Deburring

Perforating the material results in significant inner tension as well as a considerable degree of unevenness. Consequently, every perforated sheet supplied by Metrix Group is tension levelled to reduce the tension and eliminate unevenness.

Fabrication

With a combination of specialised equipment and a network of professional partners, Metrix Group are able to produce prime quality products and solutions from a single custom-made perforated sheet to the fully formed & coated part.

Finishing

Metrix Group work with a group of strategic partners who offer a range of finishes to suit your substrate, application and location. We only use accredited applicators that offer official warranty certificates on completion of work. Read more about our range of finishes here

Express Lead Times

We pride ourselves on a 24 HR Request For Quote (RFQ) turnaround and a dedicated customer service team to follow up your quote and make sure you know where we are up to and what to expect. Speak to our technical sales staff about our whether our Express Sservice can be made available to you.

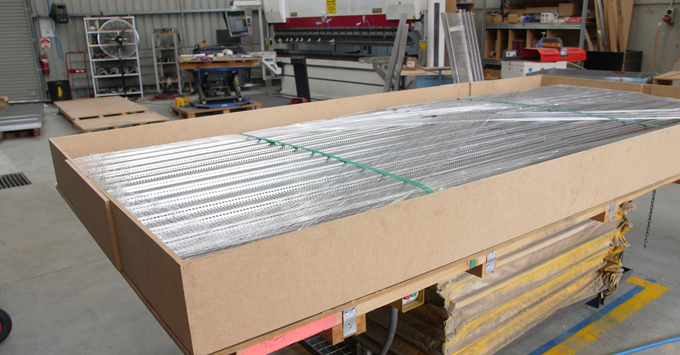

Packaging Team

Product is packed with foam interleaves and foam blocks (if folded) and fully enclosed in heavy- duty timber crates for maximum protection during transport.

Transport / Logistics Team

All processes are recorded via CCTV with finished packs photographed prior to dispatch. The customer is emailed with delivery details including photos of packed products and a copy of the packing list.