Customisable and Efficient

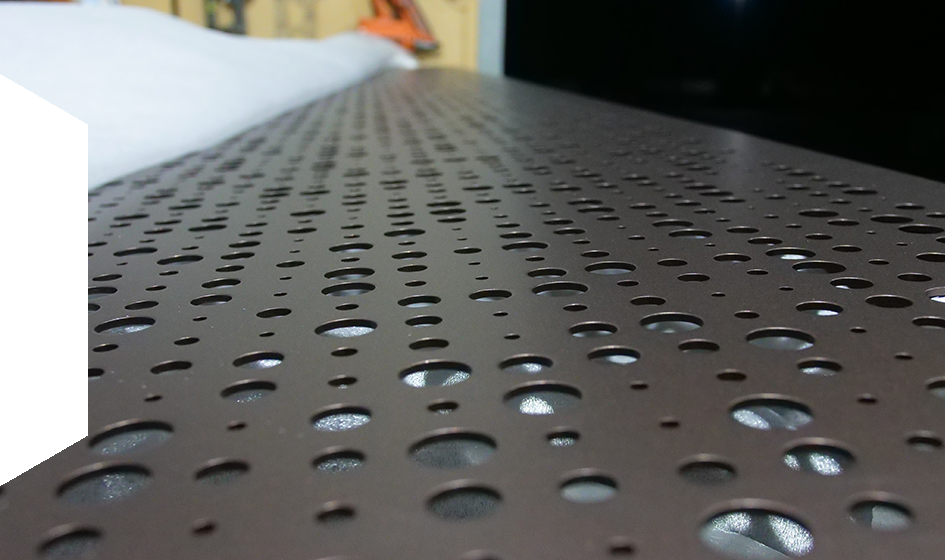

There are several methods to produce perforated metals, however the Metrix Group process utilises a method using a “die and punch” tool via high speed Computerised Numerical Control (CNC) turret machines. Utilising the latest European equipment, Metrix Group has found this process delivers the ultimate mix of design flexibility and ability to efficiently perforate a large surface of sheet very quickly.

A Punch Press allows customised single or cluster tools to be interchanged throughout the perforation process. During this process, the tool is repeatedly pressed onto the passing metal which punches holes into the sheet.

Combined with the sheet movement and the XY Axis of the Ram, Metrix Group can create highly customisable, intricate designs to suit the most discerning of imaginations.

As part of the design aesthetic and for functional purposes, a certain amount of material along the length of the sheet will be reserved as unperforated. This is done to create margins, or solid blank areas around the edges of the material.

At Metrix Group, we love working with perforated aluminium sheet. It’s strong, durable, sustainable and effective. It finishes well with a wide range of powder coating options and the new anodising techniques create beautiful colour ranges and textures.

Metrix Group stocks a wide range of metal sheet materials however all of our product is made to order. If you have an idea or you’re in need of some feedback, please feel free to book a design consultation or speak to one of our technical sales staff.