Perforated Metal Fixing Systems

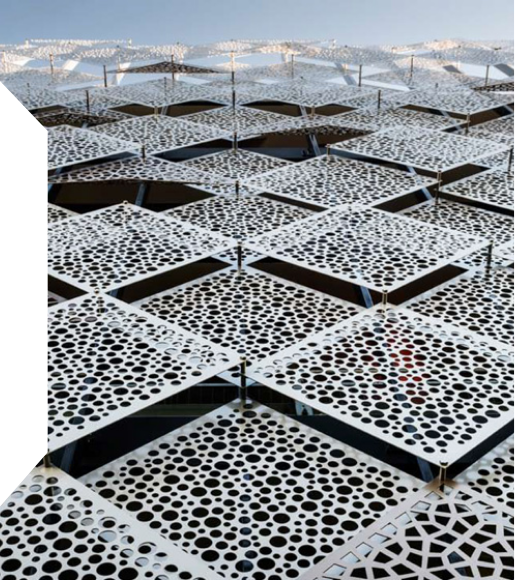

Perforated metal is versatile and used in various applications, from beautiful architectural facades and acoustic performance to retail displays. Perforated metals are also a popular way to make buildings more energy efficient and to add architectural style and beauty. However, to ensure perforated metal panels are installed correctly and securely, they must be fixed using the right system.

At Metrix Group, our five types of concealed fixing systems are of the highest quality, with isolating grommets and washers that prevent thermal expansion and buckling. Architects and Designers can have peace of mind specifying Metrix Group’s proprietary fixing systems. All Metrix Group fixing systems have been designed and engineered to relevant Australian Standards and the national building code.

PLEASE NOTE: Engineering is project-specific and contingent upon a final engineering assessment to ensure optimal performance.

Are you after a supplier for a concealed fixing system near you? For more information, reach out to Metrix Group today.

What Is A Perforated Metal Fixing System?

Concealed fixing systems and perforated fixing systems are two different methods of fixing cladding panels to a building’s facade.

Concealed fixing systems involve fixing the panels from behind, using undercut anchors or fixings in the shadow gaps. Perforated fixing systems are visible on the front of the facade.

At Metrix Group, we adhere strictly to the following Australian standard regulations for concealed fixing systems and perforated fixing systems for exterior and interior applications

AS/NZS Standard

AS/NZS 1170.1:1997

Structural design actions permanent, imposed and other actions

AS/NZS 1170.0:2002

Structural design actions general principals

AS/NZS 1170.2:2011

Structural design actions wind actions

AS/NZS 1664.1:1997

Aluminium structures part 1 Limit state design

AS/NZS 1530.1:1994

Fire resistance and non-combustibility

AS/NZS 1664.2:1997

Aluminium structures part 2 Allowable stress design

PLEASE NOTE: Engineering is project-specific and contingent upon a final engineering assessment to ensure optimal performance.

Benefits Of Metrix Group’s Perforated Metal Fixing System

Metrix Group’s concealed perforated metal fixing systems are of the highest standard used to prevent the following results and to protect the perforated metal.

DISSIMILAR METAL PROTECTION

When applying either a perforated metal fixing system or concealed fixing system, it’s essential to be aware that galvanic corrosion is caused when two differing metals come in contact with one another in the presence of an electrolyte. This weakens the structural integrity of the panel/framing and shortens the life of the coating, which is overcome with Metrix Group’s isolating grommets or washers.

NOTE: if dissimilar metal protection is not provided, this will void the powder coat manufacturer’s warranty.

SOUND ISOLATION

Vibrational frequencies are the natural frequencies at which an object will vibrate, and such vibration can damage the object or cause it to fail. With perforated steel facades, the holes in the steel can act as resonance chambers. Still, at Metrix Group, our panels bolted to a frame will transfer vibrational frequencies directly through the panel framing and any attached structure. Metrix Group isolating grommets fitted between screens and framing also assist in absorbing structure-borne vibrations.

Our 5 Systems

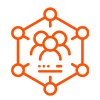

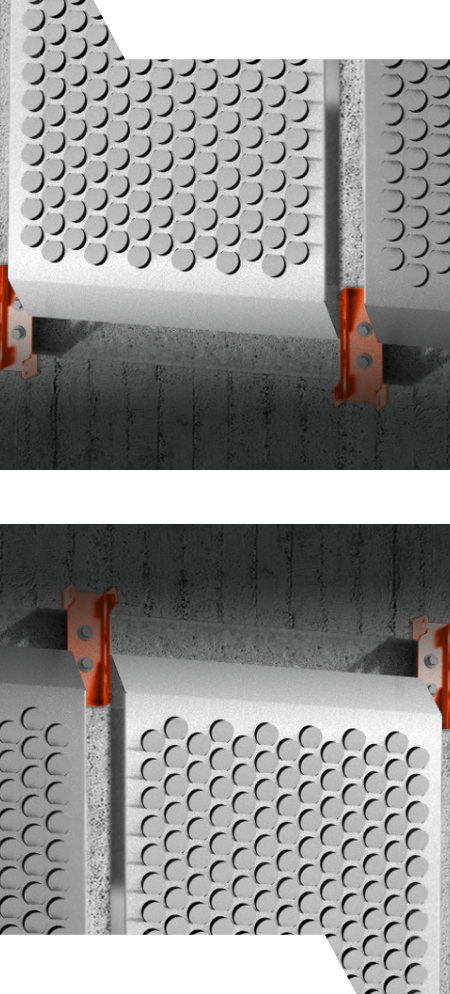

CF4000

A concealed fixing system that is quick and easy to install. This system is ideal for

Features & Benefits

- Concealed installation system

- Quick & easy installation

- Panel width up to 900mm

- Panel span up to 3600mm

- Varied panel depth 50-150mm

- Metrix Group Thermal expansion system

- Metrix Group dissimilar metal corrosion protection

- Fire resistance and non-combustibility AS/NZS 1530.1:1994

Some of the best uses for the Metrix Group's CF4000 concealed fixing system for perforated metal sheets include:

- Exterior cladding:

- Internal acoustic panels

- Balustrades and handrails

- Screens and sunshades

In addition to these uses, the CF4000 system can also be used for various other applications, such as signage, fencing, and decorative panels. The system is versatile and adaptable, making it a good choice for a wide range of projects.

PLEASE NOTE: Engineering is project-specific and contingent upon a final engineering assessment to ensure optimal performance.

SS3000

This fixing system spans up to 3.3 metres eliminating any support structure.

Features & Benefits

- Cost-effective with no support framing

- Quick & easy installation

- Panel width up to 900mm

- Panel span up to 3300mm

- Varied panel depth 50-150mm

- Metrix Thermal expansion system

- Metrix dissimilar metal corrosion protection

- Fire resistance and non-combustibility AS/NZS 1530.1:1994

Here are some of the best uses for the Metrix Group's SS3000 concealed fixing system for perforated metal sheets:

- Interior cladding

- Internal acoustic panels

- Balustrades and handrails

- Screens and sunshades

PLEASE NOTE: Engineering is project-specific and contingent upon a final engineering assessment to ensure optimal performance.

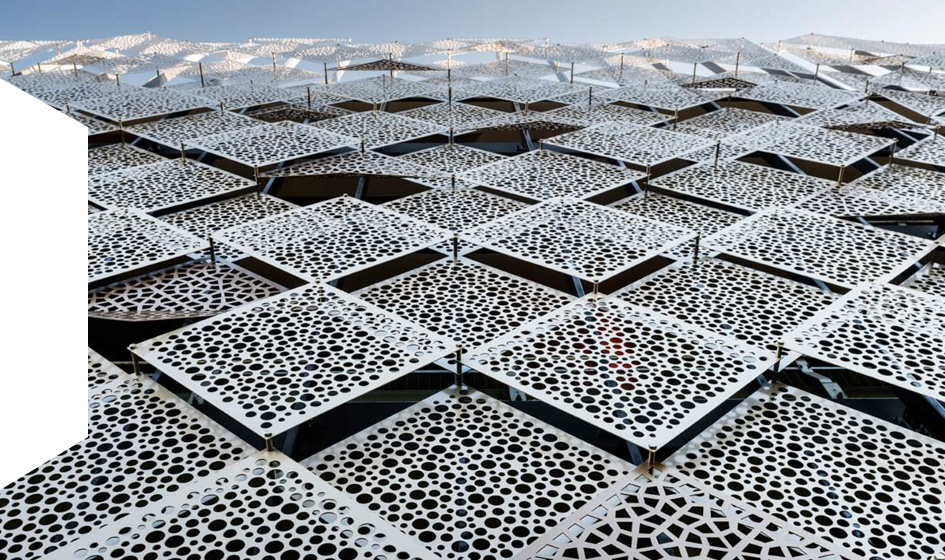

TS1200

The varying panel depth of this system creates a unique 3-dimensional effect.

Features & Benefits

- Quick & easy installation

- Tiles can feature different patterns

- Tiles up to 1200 x 1200mm

- Panel depth can vary up to 150mm

- Metrix Thermal expansion system

- Metrix dissimilar metal corrosion protection

- Fire resistance and non-combustibility AS/NZS 1530.1:1994

The Metric Group's TS1200 fixing system is cost-effective and versatile for fixing perforated sheet metal. It can be used in a variety of applications, including:

- Wall cladding

- Ceiling panels

- Partitions

- Shelving

- Railings

- Fencing

PLEASE NOTE: Engineering is project-specific and contingent upon a final engineering assessment to ensure optimal performance.

DD600

This fixing system spans up to 3.3 metres eliminating any support structure.

Features & Benefits

- Cost-effective with no support framing

- Quick & easy installation

- Panel width up to 900mm

- Panel span up to 3300mm

- Varied panel depth 50-150mm

- Metrix Thermal expansion system

- Metrix dissimilar metal corrosion protection

- Fire resistance and non-combustibility AS/NZS 1530.1:1994

The Metric Group's DD600 fixing system is a concealed fixing system for perforated sheet metal. It can be used in a variety of applications, including:

- Wall cladding

- Ceiling panels

- Partitions

- Shelving

- Railings

- Fencing

PLEASE NOTE: Engineering is project-specific and contingent upon a final engineering assessment to ensure optimal performance.

FF600

This fixing system offers flexibility in panel size and shape.

Features & Benefits

- Flexibility in panel size and shape

- Large panel size up to 3600 X 1500mm

- Metrix Thermal expansion system

- Metrix dissimilar metal corrosion protection

- Fire resistance and non-combustibility AS/NZS 1530.1:1994

The Metric Group's FF600 fixing system can be used in a variety of applications, including:

- Wall cladding

- Ceiling panels

- Partitions

- Shelving

- Railings

- Fencing

PLEASE NOTE: Engineering is project-specific and contingent upon a final engineering assessment to ensure optimal performance.

Why It Is Important To Use A Fire-

Resistant Concealed Fixing System

It is essential to use a fire-resistant concealed fixing system for perforated metal engineering for several reasons.

Fire safety: Perforated sheet metal is often used in commercial and industrial settings where fire safety is a high priority. A fire-resistant concealed fixing system helps to prevent the spread of fire by providing a barrier between the sheet metal and the supporting structure.

Durability: A fire-resistant concealed fixing system is more durable than traditional fixing methods. This is because the fixings are hidden from view, which protects them from damage.

Ease of installation: A fire-resistant concealed fixing system is also relatively easy to install. This can save time and money and minimises disruption to the surrounding area.

All Metrix Group fixing systems feature isolating grommets and have fire resistance and non-combustibility certification pertaining to AS/NZS 1530.3-1999.

Contact Metrix Group Today

Perforated metal is a sustainable material that can be recycled. This makes it a good choice for projects that are environmentally conscious.

If you are looking for a high-quality concealed perforated metal fixing system from a trusted Australian-owned company operating in Melbourne, contact Metrix Group today. We punch above our weight! Contact us here.

YOU’VE COME TO THE RIGHT PLACE.

Fill in the form below and we’ll get back to you within 24 hrs.